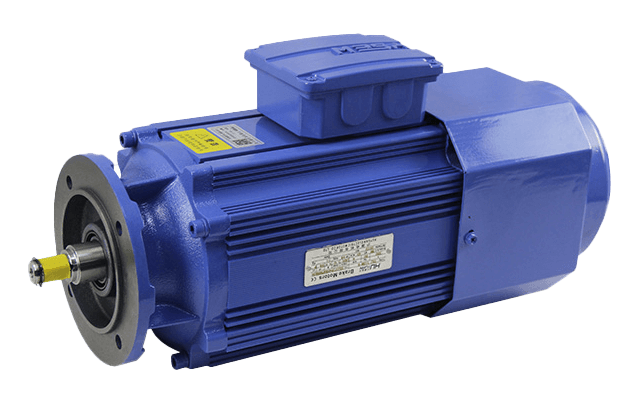

High Efficiency Hard Tooth Surface Reducer Special Direct Motor

Overview

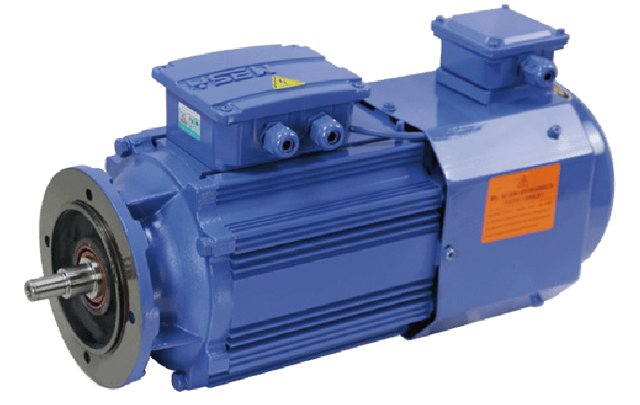

In the same model, it can be matched with various flange covers to meet the requirements of different installation dimensions. The I-shaped flange end cover is selected, the shaft is quenched and tempered, and the bearing grade is increased at the same time, which can improve the bearing capacity, increase the safety factor and the service life of the motor. Widely used in hard tooth surface reducers, it plays a role of fast braking and stopping in various mechanical equipment, conveying machinery, lifting equipment, metallurgy, mining, chemical, pharmaceutical and other industries. It is especially suitable for equipment and occasions with high safety requirements and frequent emergency stops, which can effectively save energy and improve production efficiency.

Features

1. Compact structure: The integrated design of electromagnetic brake and motor saves installation space.

2. Quick braking: The electromagnetic brake can quickly and effectively brake the motor, ensuring the stopping and safety of the equipment.

3. Good Electromagnetic compatibility: Electromagnetic braking motor has low electromagnetic radiation and electromagnetic interference, and will not cause interference to surrounding equipment.

4. Efficient and energy-saving: Adopting an efficient motor design and braking system, it has lower energy consumption and higher efficiency.

5. High reliability: The electromagnetic brake adopts high-quality electromagnetic materials and braking systems, which have stable braking performance and reliability.

Operation Condition

Ambient temperature: -15℃-+40℃

Duty: S1

Cooling method: IC 0141(Fan cooling fan)

Rated voltage: 3 80V(Other voltages required separate agreement)

Rated frequency: 50Hz, 60Hz

Insulation class: F

Protection class: IP54. IP55

Product Parameters

|

Type |

Ratedpower |

Speed |

Current |

Locked-rotor current | Locked-rotor torque | Pull-out torque |

Static braking |

Energizing power |

No-lood brake log time | |

|

KW |

(r/min) |

In(A) |

|

Rated Torque Tst/TN |

Rated Torque Tmax/TN |

torque (N.m) |

(W) |

(S) |

||

|

Synchronous 3000(r/min) |

||||||||||

|

YEJ |

80M1-2 |

0.75 |

2840 |

1.77 |

6.1 |

2.2 |

2.3 |

7.5 |

99 |

0.20 |

|

YEJ |

80M2-2 |

1.1 |

2840 |

2.50 |

7.0 |

2.2 |

2.3 |

7.5 |

99 |

0.20 |

|

YEJ |

90S-2 |

1.5 |

2840 |

3.34 |

7.0 |

2.2 |

2.3 |

13 |

99 |

0.25 |

|

YEJ |

90L-2 |

2.2 |

2840 |

4.73 |

7.0 |

2.2 |

2.3 |

13 |

99 |

0.25 |

|

YEJ |

100L-2 |

3.0 |

2860 |

6.19 |

7.5 |

2.2 |

2.3 |

30 |

99 |

0.30 |

|

YEJ |

112M-2 |

4.0 |

2880 |

8.05 |

7.5 |

2.2 |

2.3 |

30 |

170 |

0.35 |

|

YEJ |

132S1-2 |

5.5 |

2910 |

10.91 |

7.5 |

2.2 |

2.3 |

80 |

170 |

0.40 |

|

YEJ |

132S2-2 |

7.5 |

2910 |

14.70 |

7.5 |

2.2 |

2.3 |

80 |

170 |

0.40 |

|

YEJ |

160M1-2 |

11 |

2920 |

21.00 |

7.5 |

2.2 |

2.3 |

150 |

170 |

0.50 |

|

YEJ |

160M2-2 |

15 |

2920 |

28.36 |

7.5 |

2.2 |

2.3 |

150 |

170 |

0.50 |

|

YEJ |

160L-2 |

18.5 |

2920 |

34.36 |

7.5 |

2.2 |

2.3 |

150 |

170 |

0.50 |

|

YEJ |

180M-2 |

22 |

2930 |

40.68 |

7.5 |

2.0 |

2.3 |

200 |

170 |

0.60 |

|

YEJ |

200L1-2 |

30 |

2940 |

55.05 |

7.5 |

2.0 |

2.3 |

300 |

170 |

0.70 |

|

YEJ |

200L2-2 |

37 |

2960 |

67.53 |

7.5 |

2.0 |

2.3 |

300 |

170 |

0.70 |

|

YEJ |

225M-2 |

45 |

2960 |

81.77 |

7.5 |

2.0 |

2.3 |

450 |

170 |

0.80 |

|

Synchronous 1500r/min |

||||||||||

|

YEJ |

711-4 |

0.25 |

1390 |

0.76 |

5.2 |

2.1 |

2.2 |

4 |

99 |

0.2 |

|

YEJ |

712-4 |

0.37 |

1390 |

1.07 |

5.2 |

2.1 |

2.2 |

4 |

99 |

0.2 |

|

YEJ |

80M1-4 |

0.55 |

1390 |

1.48 |

5.2 |

2.4 |

2.3 |

7.5 |

99 |

0.20 |

|

YEJ |

80M2-4 |

0.75 |

1390 |

1.88 |

6.0 |

2.3 |

2.3 |

7.5 |

99 |

0.20 |

|

YEJ |

90S-4 |

1.1 |

1390 |

2.67 |

6.0 |

2.3 |

2.3 |

13 |

99 |

0.25 |

|

YEJ |

90L-4 |

1.5 |

1390 |

3.48 |

6.0 |

2.3 |

2.3 |

13 |

99 |

0.25 |

|

YEJ |

100L1-4 |

2.2 |

1410 |

4.90 |

7.0 |

2.3 |

2.3 |

30 |

99 |

0.30 |

|

YEJ |

100L2-4 |

3.0 |

1410 |

6.50 |

7.0 |

2.3 |

2.3 |

30 |

99 |

0.30 |

|

YEJ |

112M-4 |

4.0 |

1435 |

8.56 |

7.0 |

2.3 |

2.3 |

30 |

170 |

0.35 |

|

YEJ |

132S-4 |

5.5 |

1440 |

11.48 |

7.0 |

2.3 |

2.3 |

80 |

170 |

0.40 |

|

YEJ |

132M-4 |

7.5 |

1440 |

15.29 |

7.0 |

2.3 |

2.3 |

80 |

170 |

0.40 |

|

YEJ |

160M-4 |

11 |

1460 |

22.16 |

7.0 |

2.3 |

2.3 |

150 |

170 |

0.50 |

|

YEJ |

160L-4 |

15 |

1460 |

29.59 |

7.5 |

2.2 |

2.3 |

150 |

170 |

0.50 |

|

YEJ |

180M-4 |

18.5 |

1470 |

35.84 |

7.5 |

2.2 |

2.3 |

200 |

170 |

0.60 |

|

YEJ |

180L-4 |

22 |

1470 |

42.43 |

7.5 |

2.2 |

2.3 |

200 |

170 |

0.60 |

|

YEJ |

200L-4 |

30 |

1470 |

57.42 |

7.2 |

2.2 |

2.3 |

300 |

170 |

0.70 |

|

YEJ |

225S-4 |

37 |

1475 |

69.70 |

7.2 |

2.2 |

2.3 |

450 |

170 |

0.80 |

|

YEJ |

225M-4 |

45 |

1475 |

84.41 |

7.2 |

2.2 |

2.3 |

450 |

170 |

0.80 |

|

Synchronous 1000r/min |

||||||||||

|

YEJ |

90S-6 |

0.75 |

910 |

2.09 |

5.5 |

2.2 |

2.1 |

13 |

99 |

0.25 |

|

YEJ |

90L-6 |

1.1 |

910 |

2.93 |

5.5 |

2.0 |

2.1 |

13 |

99 |

0.25 |

|

YEJ |

100L-6 |

1.5 |

920 |

3.81 |

5.5 |

2.0 |

2.1 |

30 |

99 |

0.30 |

|

YEJ |

112M-6 |

2.2 |

935 |

5.38 |

6.5 |

2.0 |

2.1 |

30 |

170 |

0.35 |

|

YEJ |

132S-6 |

3.0 |

960 |

7.20 |

6.5 |

2.0 |

2.1 |

80 |

170 |

0.40 |

|

YEJ |

132M1-6 |

4.0 |

960 |

9.45 |

6.5 |

2.1 |

2.1 |

80 |

170 |

0.40 |

|

YEJ |

132M2-6 |

5.5 |

960 |

12.62 |

6.5 |

2.1 |

2.1 |

80 |

170 |

0.40 |

|

YEJ |

160M-6 |

7.5 |

970 |

16.97 |

6.5 |

2.1 |

2.1 |

150 |

170 |

0.50 |

|

YEJ |

160L-6 |

11 |

970 |

24.16 |

6.5 |

2.0 |

2.1 |

150 |

170 |

0.50 |

|

YEJ |

180L-6 |

15 |

970 |

31.37 |

7.0 |

2.0 |

2.1 |

200 |

170 |

0.60 |

|

YEJ |

200L1-6 |

18.5 |

980 |

38.39 |

7.0 |

2.0 |

2.1 |

300 |

170 |

0.70 |

|

YEJ |

200L2-6 |

22 |

980 |

44.30 |

7.0 |

2.1 |

2.1 |

300 |

170 |

0.70 |

|

YEJ |

225M-6 |

30 |

985 |

59.17 |

7.0 |

2.1 |

2.1 |

450 |

170 |

0.80 |

|

Synchronous 750r/min |

||||||||||

|

YEJ |

132S-8 |

2.2 |

705 |

6.0 |

6.0 |

2.0 |

2.1 |

80 |

170 |

0.40 |

|

YEJ |

132M-8 |

3.0 |

705 |

7.9 |

6.0 |

1.8 |

2.0 |

80 |

170 |

0.40 |

|

YEJ |

160M1-8 |

4.0 |

720 |

10.3 |

6.0 |

1.8 |

2.0 |

150 |

170 |

0.50 |

|

YEJ |

160M2-8 |

5.5 |

720 |

13.6 |

6.0 |

1.9 |

2.0 |

150 |

170 |

0.50 |

|

YEJ |

160L-8 |

7.5 |

720 |

17.8 |

6.0 |

2.0 |

2.0 |

150 |

170 |

0.50 |

|

YEJ |

180L-8 |

11 |

730 |

25.1 |

6.6 |

2.0 |

2.0 |

200 |

170 |

0.60 |

|

YEJ |

200L-8 |

15 |

730 |

34.1 |

6.6 |

2.0 |

2.0 |

300 |

170 |

0.70 |

|

YEJ |

225S-8 |

18.5 |

735 |

41.1 |

6.6 |

1.9 |

2.0 |

450 |

170 |

0.80 |

|

YEJ |

225M-8 |

22 |

735 |

47.4 |

6.6 |

1.9 |

2.0 |

450 |

170 |

0.80 |