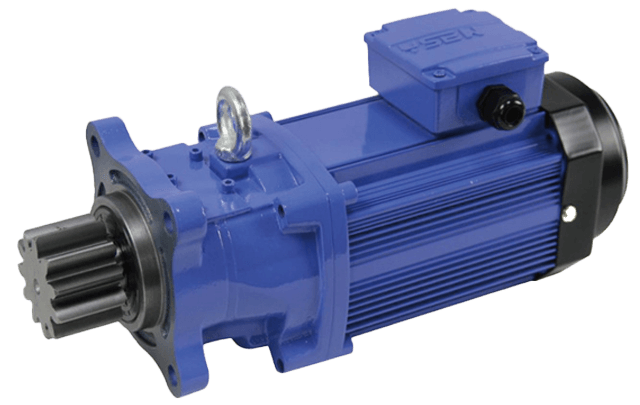

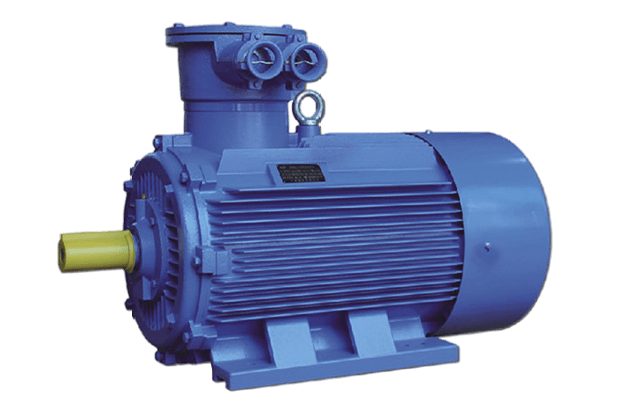

Hard Tooth Surface Reducer Special Frequency Conversion Motol

Overview

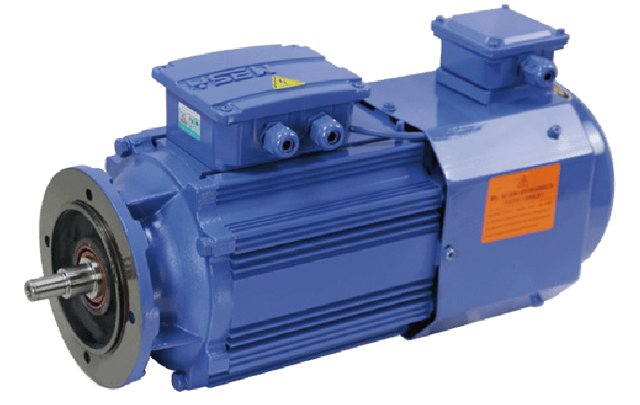

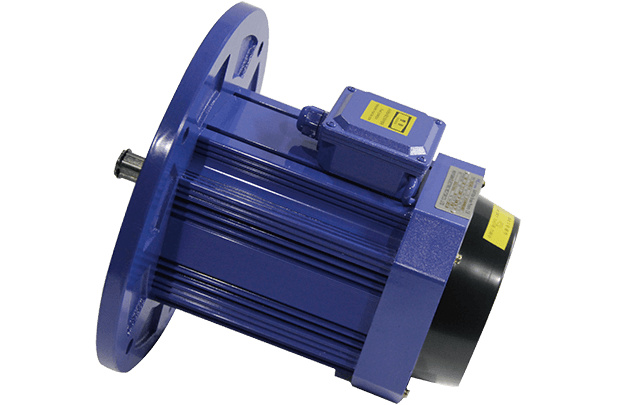

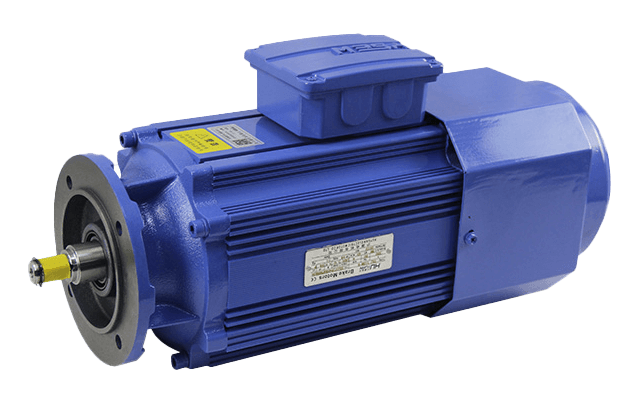

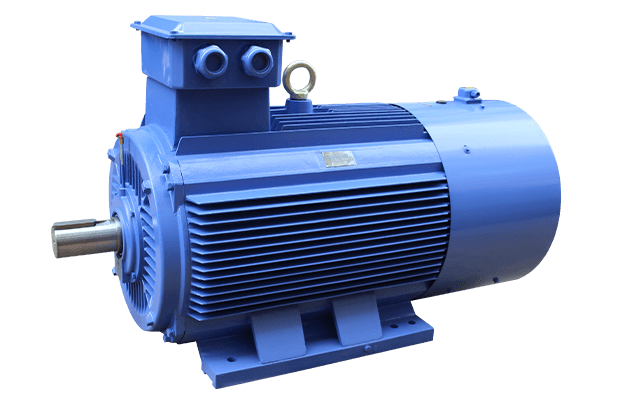

The machine base material is aluminum drawing and cast iron, and both the flange end structure and the bearing seat have been improved and adjusted. In the same model, it can be matched with various flange covers to meet the requirements of different installation dimensions. The I-shaped flange end cover is selected, the shaft is quenched and tempered, and the bearing grade is increased at the same time, which can improve the bearing capacity, increase the safety factor and the service life of the motor. It is mainly used to cooperate with the hard tooth surface reducer to realize the rotation of the reducer and output the speed suitable for the working equipment. It is widely used in various mechanical equipment that requires deceleration transmission, such as manufacturing, mining, metallurgy, construction, Chemical, cement and other industries.

Features

1. Wide power range: The YZP series variable frequency three-phase asynchronous motor has a power range of 0.55kW to 315kW, suitable for hard toothed reducers with different power requirements.

2. Efficient and energy-saving: Adopting advanced design and manufacturing technology, it has the characteristics of high efficiency and low energy consumption, which can effectively reduce energy consumption.

3. Reliable and stable: Made of high-quality materials and exquisite craftsmanship, it has good durability and stability, and can run for a long time without damage.

4. Low noise: Adopting a low noise design, it has low noise during operation and can provide a quiet working environment.

Operation Condition

Ambient temperature: -15℃-+40℃

Duty: S3

Altitude: Not exceed 1000m

Cooling method: Axizi flow tən

Rated voltage: 380V(Other voltages reguired separale agreement)

Rated frequency: 5~100Hz

Insulation c!ass: F, H

Protection class: IP54.IP55

Product Characteristic

1. Efficient and energy-saving: Adopting frequency converter speed control, it can automatically adjust the speed, effectively reduce energy consumption, and improve work efficiency.

2. Stable and reliable: Adopting high-quality materials and precision manufacturing processes, it has the characteristics of durability, stable operation, and high reliability.

3. High reliability: The motor adopts durable bearings and special materials, which provide strong corrosion resistance and high load capacity, as well as high reliability and long-term service life.

Product Parameters

|

Type |

kW |

Current A |

r/min |

N.m |

|

Axial flow fan |

Constant Torque Hz |

Constant Output |

||

|

(V) |

(W) |

|||||||||

|

Synchronous 1500r/min |

||||||||||

|

YZP |

71M1-4 |

0.25 |

0.81 |

1330 |

1.8 |

0.012 |

380 |

50 |

3~50 |

50~100 |

|

YZP |

71M2-4 |

0.37 |

1.1 |

1330 |

2.66 |

0.012 |

380 |

50 |

3~50 |

50~100 |

|

YZP |

80M1-4 |

0.55 |

1.48 |

1390 |

3.67 |

0.012 |

380 |

50 |

3~50 |

50~100 |

|

YZP |

80M2-4 |

0.75 |

1.88 |

1390 |

5.01 |

0.012 |

380 |

50 |

3~50 |

50~100 |

|

YZP |

90S-4 |

1.1 |

2.67 |

1390 |

7.35 |

0.012 |

380 |

50 |

3~50 |

50~100 |

|

YZP |

90L-4 |

1.5 |

3.48 |

1390 |

10 |

0.012 |

380 |

50 |

3~50 |

50~100 |

|

YZP |

100L1-4 |

2.2 |

4.90 |

1410 |

14.6 |

0.012 |

380 |

50 |

3~50 |

50~100 |

|

YZP |

112M1-4 |

3.0 |

6.8 |

1435 |

20.0 |

0.012 |

380 |

55 |

3~50 |

50~100 |

|

YZP |

112M2-4 |

4.0 |

8.9 |

1435 |

26.6 |

0.014 |

380 |

55 |

3~50 |

50~100 |

|

YZP |

132M1-4 |

5.5 |

11.7 |

1445 |

36.3 |

0.031 |

380 |

55 |

3~50 |

50~100 |

|

YZP |

132M2-4 |

6.3 |

13.1 |

1445 |

41.6 |

0.041 |

380 |

55 |

3~50 |

50~100 |

|

YZP |

160M1-4 |

7.5 |

16.0 |

1455 |

49.2 |

0.07 |

380 |

80 |

3~50 |

50~100 |

|

YZP |

160M2-4 |

11 |

23.4 |

1455 |

72.2 |

0.092 |

380 |

80 |

3~50 |

50~100 |

|

YZP |

160L-4 |

15 |

30.5 |

1455 |

98.5 |

0.117 |

380 |

80 |

3~50 |

50~100 |

|

YZP |

180L-4 |

22 |

43.2 |

1465 |

143 |

0.198 |

380 |

80 |

3~50 |

50~100 |

|

YZP |

200L-4 |

30 |

58.3 |

1475 |

194 |

0.346 |

380 |

150 |

3~50 |

50~100 |

|

YZP |

225M-4 |

37 |

70.3 |

1480 |

239 |

0.665 |

380 |

200 |

3~50 |

50~100 |

|

YZP |

250M1-4 |

45 |

86.5 |

1480 |

290 |

0.789 |

380 |

230 |

3~50 |

50~100 |

|

YZP |

250M2-4 |

55 |

104.5 |

1480 |

355 |

0.892 |

380 |

230 |

3~50 |

50~100 |

|

YZP |

280S1-4 |

63 |

121.1 |

1485 |

405 |

1.468 |

380 |

320 |

3~50 |

50~100 |

|

YZP |

280S2-4 |

75 |

141.3 |

1485 |

482 |

1.631 |

380 |

320 |

3~50 |

50~100 |

|

YZP |

280M-4 |

90 |

166.9 |

1485 |

579 |

1.955 |

380 |

320 |

3~50 |

50~100 |

|

YZP |

315S1-4 |

110 |

205.7 |

1485 |

707 |

3.979 |

380 |

370 |

3~50 |

50~100 |

|

YZP |

315M-4 |

132 |

243.9 |

1485 |

849 |

4.544 |

380 |

370 |

3~50 |

50~100 |

|

YZP |

355M-4 |

160 |

290.8 |

1490 |

1026 |

7.405 |

380 |

370 |

3~50 |

50~100 |

|

YZP |

355L1-4 |

200 |

353.6 |

1490 |

1282 |

8.767 |

380 |

600 |

3~50 |

50~100 |

|

YZP |

355L2-4 |

250 |

441.9 |

1490 |

1602 |

10.296 |

380 |

600 |

3~50 |

50~100 |

|

Synchronous 1000r/min |

||||||||||

|

YZP |

112M1-6 |

1.5 |

3.9 |

940 |

15.2 |

0.013 |

380 |

55 |

3~50 |

50~100 |

|

YZP |

112M2-6 |

2.2 |

5.6 |

940 |

22.4 |

0.017 |

380 |

55 |

3~50 |

50~100 |

|

YZP |

132M1-6 |

3 |

7.4 |

960 |

29.8 |

0.035 |

380 |

55 |

3~50 |

50~100 |

|

YZP |

132M2-6 |

4 |

9.6 |

960 |

39.8 |

0.046 |

380 |

55 |

3~50 |

50~100 |

|

YZP |

160M1-6 |

5.5 |

12.5 |

965 |

54.4 |

0.086 |

380 |

80 |

3~50 |

50~100 |

|

YZP |

160M2-6 |

7.5 |

17.0 |

965 |

74.2 |

0.11 |

380 |

80 |

3~50 |

50~100 |

|

YZP |

160L-6 |

11 |

24.3 |

965 |

109 |

0.145 |

380 |

80 |

3~50 |

50~100 |

|

YZP |

180L-6 |

15 |

32.0 |

975 |

147 |

0.253 |

380 |

80 |

3~50 |

50~100 |

|

YZP |

200L-6 |

22 |

47.0 |

980 |

214 |

0.482 |

380 |

150 |

3~50 |

50~100 |

|

YZP |

225M-6 |

30 |

59.3 |

985 |

291 |

0.785 |

380 |

200 |

3~50 |

50~100 |

|

YZP |

250M1-6 |

37 |

71.1 |

980 |

361 |

1.153 |

380 |

230 |

3~50 |

50~100 |

|

YZP |

250M2-6 |

45 |

86.4 |

980 |

439 |

1.351 |

380 |

230 |

3~50 |

50~100 |

|

YZP |

280S1-6 |

55 |

106.3 |

985 |

533 |

2.227 |

380 |

320 |

3~50 |

50~100 |

|

YZP |

280S2-6 |

63 |

120.3 |

985 |

611 |

2.477 |

380 |

320 |

3~50 |

50~100 |

|

YZP |

280M-6 |

75 |

140.8 |

985 |

727 |

2.857 |

380 |

320 |

3~50 |

50~100 |

|

YZP |

315S1-6 |

90 |

172.1 |

990 |

868 |

5.216 |

380 |

370 |

3~50 |

50~100 |

|

YZP |

315M-6 |

110 |

209.6 |

990 |

1061 |

5.887 |

380 |

370 |

3~50 |

50~100 |

|

YZP |

355M-6 |

132 |

251.0 |

990 |

1273 |

9.726 |

380 |

600 |

3~50 |

50~100 |

|

YZP |

355L1-6 |

160 |

302.6 |

990 |

1543 |

10.957 |

380 |

600 |

3~50 |

50~100 |

|

YZP |

355L2-6 |

200 |

373.9 |

990 |

1929 |

13.1 |

380 |

600 |

3~50 |

50~100 |

|

YZP |

400L1-6 |

250 |

473.2 |

990 |

2388 |

22.8 |

380 |

2200 |

3~50 |

50-100 |

|

YZP |

400L2-6 |

300 |

567.8 |

990 |

2865 |

25.8 |

380 |

2200 |

3~50 |

50-100 |

|

Synchronous 750r/min |

||||||||||

|

YZP |

132M1-8 |

2.2 |

6.0 |

710 |

29.6 |

0.035 |

380 |

55 |

3~50 |

50~100 |

|

YZP |

132M2-8 |

3 |

8.1 |

710 |

40.4 |

0.046 |

380 |

55 |

3~50 |

50~100 |

|

YZP |

160M1-8 |

4 |

10.0 |

720 |

53.1 |

0.082 |

380 |

80 |

3~50 |

50~100 |

|

YZP |

160M2-8 |

5.5 |

13.8 |

720 |

73.0 |

0.11 |

380 |

80 |

3~50 |

50~100 |

|

YZP |

160L-8 |

7.5 |

18.1 |

720 |

99.5 |

0.149 |

380 |

80 |

3~50 |

50~100 |

|

YZP |

180L-8 |

11 |

26.3 |

725 |

145 |

0.253 |

380 |

80 |

3~50 |

50~100 |

|

YZP |

200L-8 |

15 |

36.0 |

730 |

196 |

0.461 |

380 |

150 |

3~50 |

50~100 |

|

YZP |

225M-8 |

22 |

49.5 |

725 |

290 |

0.808 |

380 |

200 |

3~50 |

50~100 |

|

YZP |

250M1-8 |

30 |

64.2 |

735 |

390 |

1.227 |

380 |

230 |

3~50 |

50~100 |

|

YZP |

250M2-8 |

37 |

78.2 |

735 |

481 |

1.45 |

380 |

230 |

3~50 |

50~100 |

|

YZP |

280S1-8 |

45 |

96.5 |

740 |

581 |

2.519 |

380 |

320 |

3~50 |

50~100 |

|

YZP |

280M-8 |

55 |

115.8 |

740 |

710 |

2.978 |

380 |

320 |

3~50 |

50~100 |

|

YZP |

315S1-8 |

63 |

134.0 |

740 |

813 |

6.255 |

380 |

370 |

3~50 |

50~100 |

|

YZP |

315S2-8 |

75 |

157.4 |

740 |

968 |

7.036 |

380 |

370 |

3~50 |

50~100 |

|

YZP |

315M-8 |

90 |

188.5 |

740 |

1162 |

7.908 |

380 |

370 |

3~50 |

50~100 |

|

YZP |

355M-8 |

110 |

227.9 |

740 |

1420 |

9.792 |

380 |

600 |

3~50 |

50~100 |

|

YZP |

355L1-8 |

132 |

272.1 |

740 |

1704 |

11.588 |

380 |

600 |

3~50 |

50~100 |

|

YZP |

355L2-8 |

160 |

329.8 |

740 |

2065 |

13.781 |

380 |

600 |

3~50 |

50~100 |

|

YZP |

400L1-8 |

200 |

399.5 |

745 |

2547 |

22.8 |

380 |

2200 |

3~50 |

50-100 |

|

YZP |

400L2-8 |

250 |

499.3 |

745 |

3183 |

25.8 |

380 |

2200 |

3~50 |

50-100 |

|

Synchronous 600r/min |

||||||||||

|

YZP |

280S-10 |

37 |

88 |

590 |

599 |

2.519 |

380 |

320 |

3~50 |

50~100 |

|

YZP |

280M-10 |

45 |

107 |

590 |

728 |

2.978 |

380 |

320 |

3~50 |

50~100 |

|

YZP |

315S1-10 |

55 |

126.8 |

590 |

890 |

6.428 |

380 |

370 |

3~50 |

50~100 |

|

YZP |

315S2-10 |

63 |

144.5 |

590 |

1020 |

7.036 |

380 |

370 |

3~50 |

50~100 |

|

YZP |

315M-10 |

75 |

168.8 |

590 |

1214 |

7.908 |

380 |

370 |

3~50 |

50~100 |

|

YZP |

355M-10 |

90 |

203.8 |

595 |

1445 |

9.646 |

380 |

600 |

3~50 |

50~100 |

|

YZP |

355L1-10 |

110 |

246.9 |

595 |

1766 |

11.588 |

380 |

600 |

3~50 |

50~100 |

|

YZP |

355L2-10 |

132 |

292.3 |

595 |

2119 |

13.781 |

380 |

600 |

3~50 |

50~100 |

|

YZP |

400L1-10 |

160 |

341.4 |

595 |

2550 |

23.6 |

380 |

2200 |

3~50 |

50-100 |

|

YZP |

400L2-10 |

200 |

426.7 |

595 |

3183 |

25.2 |

380 |

2200 |

3~50 |

50-100 |