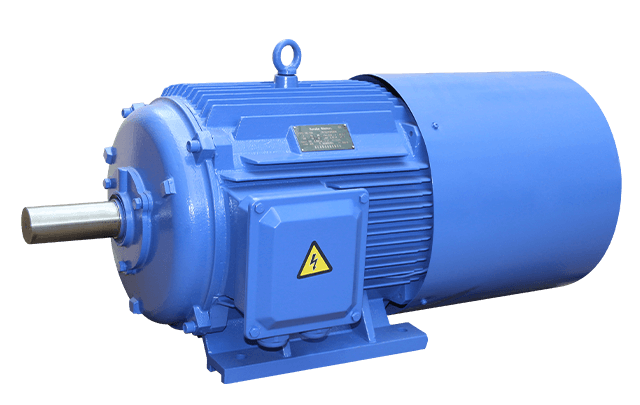

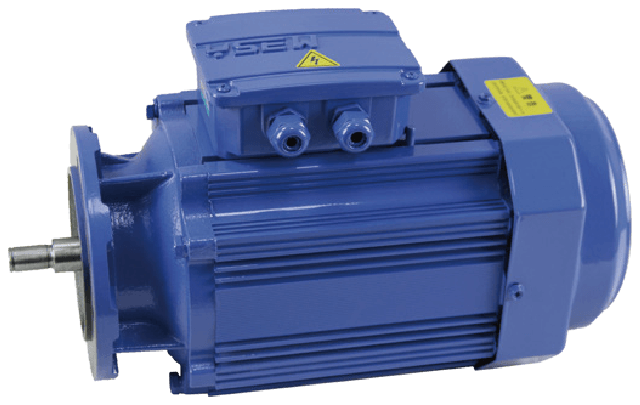

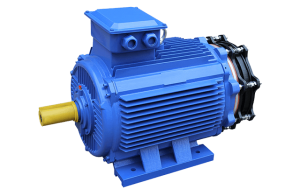

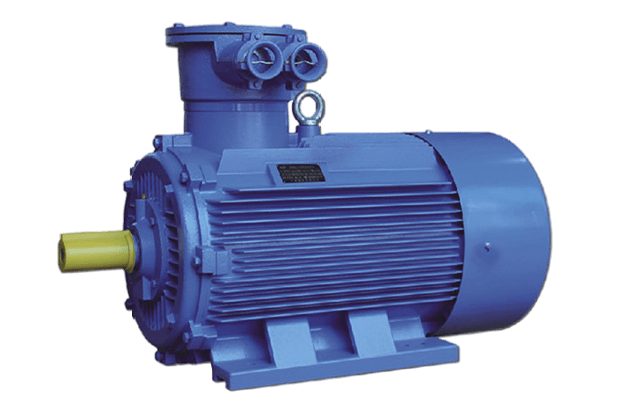

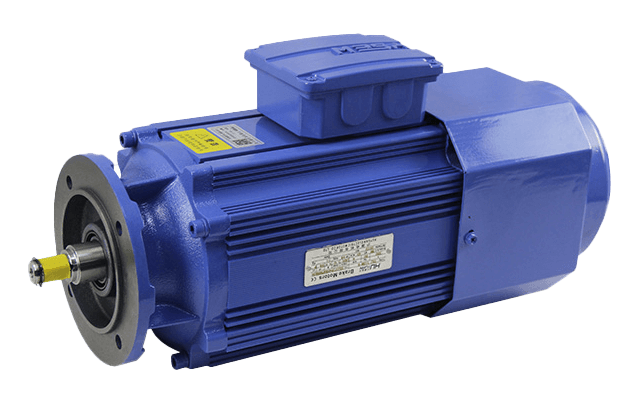

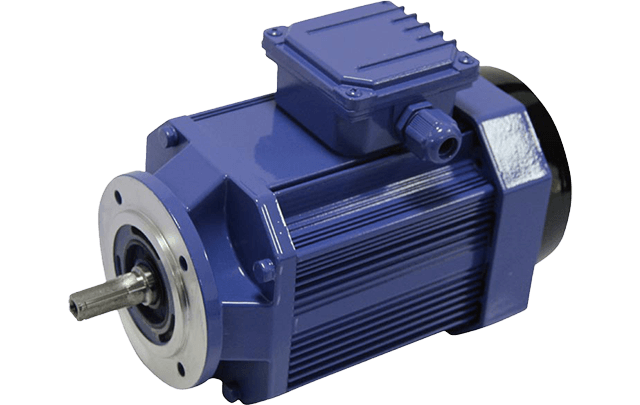

Electromagnetic Brake Three – Phase Asynchronous Motor

Product Description

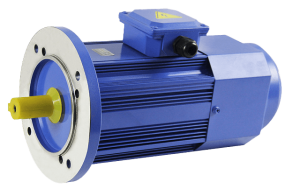

The dedicated brake motor for direct connected hard tooth surface reducers is designed specifically for the R, S, F, and K series of hard tooth surface reducers. It has various safety protection functions, such as emergency stop and braking functions, and can be used in situations where high precision, high reliability, and high efficiency are required. Improvements and adjustments have been made to the flange end structure and bearing seat, which can be paired with multiple flange covers in the same model to meet the requirements of different installation sizes. It is directly connected to the hard tooth reducer and adopts a design of high efficiency, low noise, and high reliability. It can provide high torque, high precision, and long running time power support for industrial production lines, mechanical equipment, automated production lines, etc. It is particularly suitable for situations that require high-power, high-efficiency, and low noise motors.

Operation Condition

Technical Data:

Centre height of frame: 63-1 60mm

Controller’s power:

Centre height offrame: s 100mm, AC220V (after commutate 99 V)

Centre height offrame: 112mm, AC380V (after commutatel 7 0V)

Powerrange: 0.12-45kW

Rated voltage: 380 V ororder

Rated frequency: 50Hzor 60 Hz

Protection class: IP54(orIP55)

Insulationclass: B/F Duty type: Sl

Specification

| Ratedpower | Speed | Current | Locked-rotor current | Locked-rotor torque | Pull-out torque | Static braking | No-lood brake log time (S) | |||

| Energizing power | ||||||||||

| Type | KW | (r/min) | In(A) | Rated Torque Tst/TN | Rated Torque Tmax/TN | torque (N.m) | (W) | |||

| Synchronous speed 3000(r/min) | ||||||||||

| YEJ | 80M1-2 | 0.75 | 2840 | 1.77 | 6.1 | 2.2 | 2.3 | 7.5 | 99 | 0.20 |

| YEJ | 80M2-2 | 1.1 | 2840 | 2.50 | 7.0 | 2.2 | 2.3 | 7.5 | 99 | 0.20 |

| YEJ | 90S-2 | 1.5 | 2840 | 3.34 | 7.0 | 2.2 | 2.3 | 13 | 99 | 0.25 |

| YEJ | 90L-2 | 2.2 | 2840 | 4.73 | 7.0 | 2.2 | 2.3 | 13 | 99 | 0.25 |

| YEJ | 100L-2 | 3.0 | 2860 | 6.19 | 7.5 | 2.2 | 2.3 | 30 | 99 | 0.30 |

| YEJ | 112M-2 | 4.0 | 2880 | 8.05 | 7.5 | 2.2 | 2.3 | 30 | 170 | 0.35 |

| YEJ | 132S1-2 | 5.5 | 2910 | 10.91 | 7.5 | 2.2 | 2.3 | 80 | 170 | 0.40 |

| YEJ | 132S2-2 | 7.5 | 2910 | 14.70 | 7.5 | 2.2 | 2.3 | 80 | 170 | 0.40 |

| YEJ | 160M1-2 | 11 | 2920 | 21.00 | 7.5 | 2.2 | 2.3 | 150 | 170 | 0.50 |

| YEJ | 160M2-2 | 15 | 2920 | 28.36 | 7.5 | 2.2 | 2.3 | 150 | 170 | 0.50 |

| YEJ | 160L-2 | 18.5 | 2920 | 34.36 | 7.5 | 2.2 | 2.3 | 150 | 170 | 0.50 |

| YEJ | 180M-2 | 22 | 2930 | 40.68 | 7.5 | 2.0 | 2.3 | 200 | 170 | 0.60 |

| YEJ | 200L1-2 | 30 | 2940 | 55.05 | 7.5 | 2.0 | 2.3 | 300 | 170 | 0.70 |

| YEJ | 200L2-2 | 37 | 2960 | 67.53 | 7.5 | 2.0 | 2.3 | 300 | 170 | 0.70 |

| YEJ | 225M-2 | 45 | 2960 | 81.77 | 7.5 | 2.0 | 2.3 | 450 | 170 | 0.80 |

| Synchronous speed 1500r/min | ||||||||||

| YEJ | 711-4 | 0.25 | 1390 | 0.76 | 5.2 | 2.1 | 2.2 | 4 | 99 | 0.2 |

| YEJ | 712-4 | 0.37 | 1390 | 1.07 | 5.2 | 2.1 | 2.2 | 4 | 99 | 0.2 |

| YEJ | 80M1-4 | 0.55 | 1390 | 1.48 | 5.2 | 2.4 | 2.3 | 7.5 | 99 | 0.20 |

| YEJ | 80M2-4 | 0.75 | 1390 | 1.88 | 6.0 | 2.3 | 2.3 | 7.5 | 99 | 0.20 |

| YEJ | 90S-4 | 1.1 | 1390 | 2.67 | 6.0 | 2.3 | 2.3 | 13 | 99 | 0.25 |

| YEJ | 90L-4 | 1.5 | 1390 | 3.48 | 6.0 | 2.3 | 2.3 | 13 | 99 | 0.25 |

| YEJ | 100L1-4 | 2.2 | 1410 | 4.90 | 7.0 | 2.3 | 2.3 | 30 | 99 | 0.30 |

| YEJ | 100L2-4 | 3.0 | 1410 | 6.50 | 7.0 | 2.3 | 2.3 | 30 | 99 | 0.30 |

| YEJ | 112M-4 | 4.0 | 1435 | 8.56 | 7.0 | 2.3 | 2.3 | 30 | 170 | 0.35 |

| YEJ | 132S-4 | 5.5 | 1440 | 11.48 | 7.0 | 2.3 | 2.3 | 80 | 170 | 0.40 |

| YEJ | 132M-4 | 7.5 | 1440 | 15.29 | 7.0 | 2.3 | 2.3 | 80 | 170 | 0.40 |

| YEJ | 160M-4 | 11 | 1460 | 22.16 | 7.0 | 2.3 | 2.3 | 150 | 170 | 0.50 |

| YEJ | 160L-4 | 15 | 1460 | 29.59 | 7.5 | 2.2 | 2.3 | 150 | 170 | 0.50 |

| YEJ | 180M-4 | 18.5 | 1470 | 35.84 | 7.5 | 2.2 | 2.3 | 200 | 170 | 0.60 |

| YEJ | 180L-4 | 22 | 1470 | 42.43 | 7.5 | 2.2 | 2.3 | 200 | 170 | 0.60 |

| YEJ | 200L-4 | 30 | 1470 | 57.42 | 7.2 | 2.2 | 2.3 | 300 | 170 | 0.70 |

| YEJ | 225S-4 | 37 | 1475 | 69.70 | 7.2 | 2.2 | 2.3 | 450 | 170 | 0.80 |

| YEJ | 225M-4 | 45 | 1475 | 84.41 | 7.2 | 2.2 | 2.3 | 450 | 170 | 0.80 |

| Synchronous speed 1000r/min | ||||||||||

| YEJ | 90S-6 | 0.75 | 910 | 2.09 | 5.5 | 2.2 | 2.1 | 13 | 99 | 0.25 |

| YEJ | 90L-6 | 1.1 | 910 | 2.93 | 5.5 | 2.0 | 2.1 | 13 | 99 | 0.25 |

| YEJ | 100L-6 | 1.5 | 920 | 3.81 | 5.5 | 2.0 | 2.1 | 30 | 99 | 0.30 |

| YEJ | 112M-6 | 2.2 | 935 | 5.38 | 6.5 | 2.0 | 2.1 | 30 | 170 | 0.35 |

| YEJ | 132S-6 | 3.0 | 960 | 7.20 | 6.5 | 2.0 | 2.1 | 80 | 170 | 0.40 |

| YEJ | 132M1-6 | 4.0 | 960 | 9.45 | 6.5 | 2.1 | 2.1 | 80 | 170 | 0.40 |

| YEJ | 132M2-6 | 5.5 | 960 | 12.62 | 6.5 | 2.1 | 2.1 | 80 | 170 | 0.40 |

| YEJ | 160M-6 | 7.5 | 970 | 16.97 | 6.5 | 2.1 | 2.1 | 150 | 170 | 0.50 |

| YEJ | 160L-6 | 11 | 970 | 24.16 | 6.5 | 2.0 | 2.1 | 150 | 170 | 0.50 |

| YEJ | 180L-6 | 15 | 970 | 31.37 | 7.0 | 2.0 | 2.1 | 200 | 170 | 0.60 |

| YEJ | 200L1-6 | 18.5 | 980 | 38.39 | 7.0 | 2.0 | 2.1 | 300 | 170 | 0.70 |

| YEJ | 200L2-6 | 22 | 980 | 44.30 | 7.0 | 2.1 | 2.1 | 300 | 170 | 0.70 |

| YEJ | 225M-6 | 30 | 985 | 59.17 | 7.0 | 2.1 | 2.1 | 450 | 170 | 0.80 |

| Synchronous speed 750r/min | ||||||||||

| YEJ | 132S-8 | 2.2 | 705 | 6.0 | 6.0 | 2.0 | 2.1 | 80 | 170 | 0.40 |

| YEJ | 132M-8 | 3.0 | 705 | 7.9 | 6.0 | 1.8 | 2.0 | 80 | 170 | 0.40 |

| YEJ | 160M1-8 | 4.0 | 720 | 10.3 | 6.0 | 1.8 | 2.0 | 150 | 170 | 0.50 |

| YEJ | 160M2-8 | 5.5 | 720 | 13.6 | 6.0 | 1.9 | 2.0 | 150 | 170 | 0.50 |

| YEJ | 160L-8 | 7.5 | 720 | 17.8 | 6.0 | 2.0 | 2.0 | 150 | 170 | 0.50 |

| YEJ | 180L-8 | 11 | 730 | 25.1 | 6.6 | 2.0 | 2.0 | 200 | 170 | 0.60 |

| YEJ | 200L-8 | 15 | 730 | 34.1 | 6.6 | 2.0 | 2.0 | 300 | 170 | 0.70 |

| YEJ | 225S-8 | 18.5 | 735 | 41.1 | 6.6 | 1.9 | 2.0 | 450 | 170 | 0.80 |

| YEJ | 225M-8 | 22 | 735 | 47.4 | 6.6 | 1.9 | 2.0 | 450 | 170 | 0.80 |

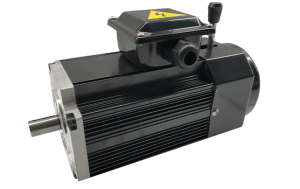

Product Characteristic

1. Reliable braking: Electromagnetic brakes generate braking force through electromagnetic principles and have reliable braking performance. They can quickly brake when the motor stops, ensuring equipment safety.

2. High reliability: The motor adopts durable bearings and special materials, which provide strong corrosion resistance and high load capacity, as well as high reliability and long-term service life.

3. High braking torque and accuracy: The brake design is reasonable, with the characteristics of high braking force and high accuracy, and can adapt to complex braking situations.

4. Easy maintenance: The electromagnetic brake and motor are separated for easy maintenance. If the electromagnetic brake needs to be replaced, only the brake needs to be replaced, without the need to replace the entire motor.

5. Safety and reliability: The electromagnetic brake motor can quickly brake to ensure equipment safety, and in the event of a power outage, the electromagnetic brake can also maintain the position of the equipment, increasing its safety.

6. Wide application range: The dedicated brake motor for the direct connected hard tooth reducer is suitable for various industrial occasions, such as production lines and mechanical equipment in metallurgy, papermaking, power, cement, etc.

In short, the dedicated brake motor for the direct connected hard tooth reducer, as a motor directly connected to the hard tooth reducer, has the characteristics of safety, reliability, high efficiency, precise control, and easy maintenance. It can provide safe, efficient, and stable power output support in various production situations, ensuring that production equipment is always in the best state.