Electromagnetic Brake AC Brake

Product Description

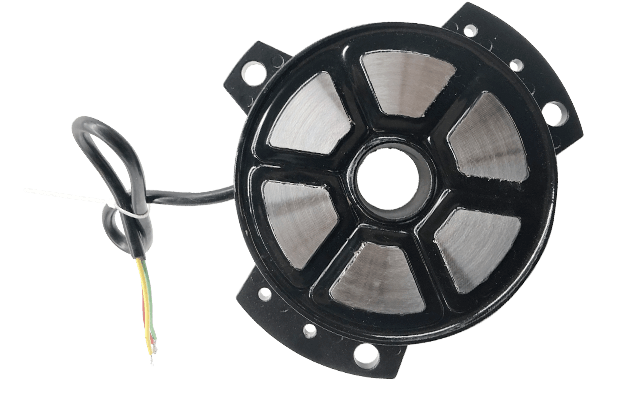

The electromagnetic AC brake is a device that uses electromagnetic action to achieve the braking function. It is mainly composed of electromagnet, power supply, control circuit and braking parts.

In the electromagnetic AC brake, the electromagnet is the core component. When the power supply supplies the electromagnet, the electromagnetic force generated can cause the braking parts to be subjected to a certain resistance, thus realizing the braking effect. By adjusting the current of the electromagnet and the parameters in the control circuit, the braking force can be adjusted and controlled.

The electromagnetic AC brake is widely used in mechanical equipment, motors and transportation tools. It has the advantages of reliable operation, fast response and easy maintenance, and can effectively realize the braking and stopping functions. Therefore, it plays an important role in industrial production and transportation.

The AC brake has no finishing diode and is directly powered by three-phase 380V power supply, which has the advantages of reliable operation, long service life, fast braking speed and accurate positioning.

The brake coil as a whole is sealed by epoxy resin, which has good waterproof and dustproof performance.

One, Product Brief

HY series (power-off) three-phase AC electromagnetic brake is a reliable safety brake. The product has a compact structure, convenient and flexible manual release, and reliable performance.

HY series three-phase AC electromagnetic brake is matched with Y2 series motor to form YEJ series electromagnetic brake three-phase asynchronous motor. The motor has beautiful appearance, fast braking, accurate positioning, and is suitable for motor use. all occasions.

Second, how it works

When the power is turned on, the electromagnet generates a strong electromagnetic force to attract the armature to compress the brake spring, and the two dual surfaces of the brake disc are separated from the pressure of the armature and the rear end cover of the motor. It can rotate flexibly. When the power is off, the armature is pressurized by the pressure of the brake spring, so that it presses the brake disc tightly, generating a strong friction braking torque, so that the rotating motor can be quickly braked to achieve accurate positioning.

Three, product features

1. Use three-phase AC power, no need for AC-DC conversion;

2. After assembly with the motor, the overall protection level reaches IP44;

3. The insulation class is F;

Four, technical parameters

| With motor seat size | Specification code | Rated static braking torque | No-load braking time | Excitation Power | Maximum working air gap | Rated working voltage | Solution | Maximum speed allowed |

| H | HY | N.m | S | W | mm | AC(V) | Connection | r/min |

| 63 | 63 | 2 | 0.20 | 30 | 0.5 | 380 | Y | 3600 |

| 71 | 71 | 4 | 0.20 | 40 | 1 | 380 | Y | 3600 |

| 80 | 80 | 7.5 | 0.20 | 50 | 1 | 380 | Y | 3600 |

| 90 | 90 | 15 | 0.20 | 60 | 1 | 380 | Y | 3600 |

| 100 | 100 | 30 | 0.20 | 80 | 1 | 380 | Y | 3600 |

| 112 | 112 | 40 | 0.25 | 100 | 1.2 | 380 | △ | 3600 |

| 132 | 132 | 75 | 0.25 | 130 | 1.2 | 380 | △ | 3600 |

| 160 | 160 | 150 | 0.35 | 150 | 1.2 | 380 | △ | 3600 |

| 180 | 180 | 200 | 0.35 | 150 | 1.2 | 380 | △ | 3600 |

| 200 | 200 | 400 | 0.35 | 350 | 1.2 | 380 | △ | 3600 |

| 225 | 225 | 600 | 0.40 | 650 | 1.2 | 380 | △ | 3600 |

| 250 | 250 | 800 | 0.50 | 900 | 1.2 | 380 | △ | 3600 |